Pollution Board to decide on future of FGD units: Minister

×

![]()

- This follows an April 2025 recommendation by a panel led by Principal Scientific Adviser Ajay Sood to do away with mandatory FGD installations.

- Currently, 92% of India’s 600 TPPs lack FGDs. If the recommendation is accepted, around 80% could be exempt from installing them.

- FGDs are used to reduce sulphur dioxide (SO₂) emissions, which contribute to air pollution and respiratory issues but also form sulphate aerosols that may slightly offset global warming.

- cited studies by CSIR and IIT Delhi, stating SO₂ emissions from Indian TPPs contribute less than 5% to human health impacts, suggesting some atmospheric sulphates may be beneficial in climate moderation.

- The government has extended deadlines for FGD compliance three times since 2017, most recently to 2027–2030.

Flue Gas and Flue Gas Desulphurisation (FGD)

(Relevant for UPSC Prelims and Mains – Environment, Pollution Control Technologies, Energy)

What is Flue Gas?

- Flue gas (exhaust or stack gas) is the by-product of fossil fuel combustion in industrial plants and power stations.

- It is expelled through chimneys or ducts (flues) and typically contains:

- Carbon dioxide (CO₂)

- Carbon monoxide (CO)

- Sulphur dioxide (SO₂)

- Nitrogen oxides (NO & NO₂)

- Water vapour, particulate matter, and trace pollutants

- The exact composition varies with fuel type and combustion conditions.

Importance of Flue Gas Analysis:

- Helps optimize air-to-fuel ratio for energy efficiency.

- Enhances burner efficiency, reducing fuel consumption.

- Essential for monitoring pollutant levels (SO₂, NOx) to comply with environmental standards.

- Prevents corrosion and protects equipment by tracking acid-forming emissions.

What is Flue Gas Desulphurisation (FGD)?

- FGD is a pollution control technology used to remove sulphur dioxide (SO₂) from flue gases.

- Primary goal: Reduce acid rain, improve air quality, and meet emission regulations.

- FGD can remove up to 90–95% of SO₂ emissions in coal-fired power plants.

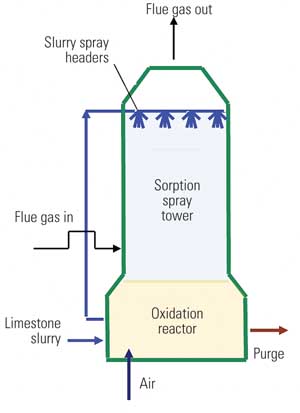

FGD Process:

- Involves spraying uncleaned flue gas with an absorbent slurry (usually lime or limestone with water) in a scrubber tower.

- Chemical reaction bonds SO₂ with the slurry, removing up to 95% of the gas.

- Other absorbents like ammonia or sodium sulphite may also be used.

FGD Methods:

- Wet scrubbing:

- Uses limestone or lime slurry (or seawater) in scrubber towers to chemically react with and remove SO₂.

- Spray-dry scrubbing:

- Similar to wet scrubbing but uses atomised sorbent slurries sprayed into a hot flue gas stream.

- Dry sorbent injection:

- Involves injecting powdered hydrated lime or other sorbents into exhaust ducts to capture SO₂ and SO₃.

- Wet sulfuric acid process:

- Recovers sulphur as commercial-grade sulfuric acid.

- SNOX process:

- Simultaneously removes sulphur dioxide, nitrogen oxides, and particulates from flue gas without using absorbents.

FAQs:

- Q1: What is

flue gas?

→ Gas emitted from combustion of fossil fuels in power or industrial plants. - Q2: Why is

flue gas analysis important?

→ For improving combustion efficiency and meeting emission regulations. - Q3:

Why is it called 'flue' gas?

→ Because it exits through ‘flues’—industrial ducts or chimneys.