India’s First Bamboo-based Ethanol Plant

Inauguration

-

By: Prime Minister Narendra Modi

-

Golaghat facility billed as world’s first green bamboo bioethanol plant

-

Facility: Assam Bio-Ethanol Private Ltd. (ABEL), Numaligarh Refinery Plant

Significance

-

World’s first green bamboo bioethanol plant

-

Part of India’s clean energy and energy self-sufficiency strategy.

-

Coincided with the foundation stone laying for a ₹7,230-crore polypropylene project at Numaligarh Refinery.

Plant Features

-

Cost: ₹5,000 crore

-

Capacity:

-

48,900 tonnes of ethanol annually

-

11,000 tonnes of acetic acid

-

19,000 tonnes of furfural

-

31,000 tonnes of food-grade liquid CO₂

-

-

Raw material: 5 lakh tonnes of green bamboo per year, sourced from Arunachal Pradesh, Assam, and other NE states.

-

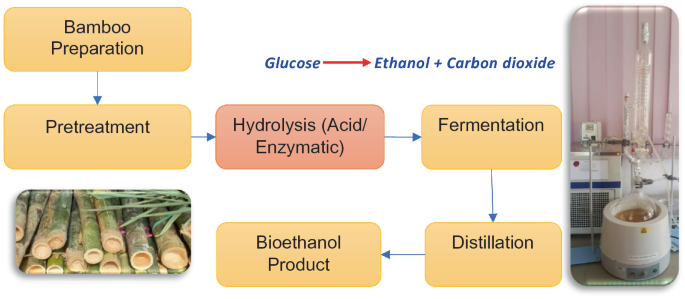

Technology: Joint venture of Numaligarh Refinery Ltd. (NRL), Finland’s Fortum and Chempolis OY.

-

“zero-waste” facility described as the world’s first to produce ethanol from green bamboo.

- "Bamboo will contribute to carbon sequestration during its growth and due to non-burning of fossil fuels, carbon emission will be drastically reduced. Use of bamboo for ethanol production also serves to conserve ground water.

- Unlike sugarcane, the most common material currently used to manufacture ethanol, bamboo requires only one fifth of water compared to water required for growing sugarcane,".

Economic & Social Impact

-

Expected to give a ₹200-crore boost to Assam’s rural economy.

-

Will benefit local farmers and tribal communities:

-

Govt. to support bamboo cultivation and procurement.

-

Promotes sustainable livelihoods in NE states.

-

-

Aligns with Make in India & Viksit Bharat 2047 vision.

Broader Energy Context

-

Reduces dependence on imported fossil fuels.

-

Complements India’s focus on:

-

Hydrocarbon exploration (deep-water mission)

-

Renewables (solar, biofuels)

-

-

Bamboo reclassified from “tree” to “grass” (2017), easing restrictions on felling and transport.