NITI Aayog Workshop on Coal Gasification Technology

Context

-

Organized by NITI Aayog.

-

Participants: Ministry of Coal, IIT Delhi, Fraunhofer IKTS (Germany), BHEL, IIT Roorkee, GAIL, CIMFR, IOCL, CIL, TFL, NLCIL, EIL, L&T, JSPL, DVC, CCL, PDIL, CSIR-IMMT, Dastur Energy.

-

Aligned with:

-

National Coal Gasification Mission

-

Make in India

-

Atmanirbhar Bharat

-

India’s Coal Profile

-

4th largest coal reserves in the world: 378 billion tonnes (199 billion tonnes proven).

-

Indian coal = high ash content (25–45%) vs low ash in global coals.

-

Challenge: earlier perception that Indian coal is “non-gasifiable” due to ash.

-

Recent trials prove feasibility through indigenous technology.

Key Workshop Highlights

-

Technology Discussions

-

Focus on fluidized bed, circulating bed, entrained flow systems.

-

Global insights from Fraunhofer IKTS, Germany.

-

Indian pilots: IIT Delhi, Thermax, BHEL, CIMFR.

-

-

Recommendations

-

Circulating fluidized bed gasification most suited for India’s high-ash coal.

-

Other technologies (entrained flow, fixed bed) unsuitable due to Indian coal ash chemistry.

-

Scale up pilot → commercial projects.

-

Integrate Carbon Capture, Utilization & Storage (CCUS).

-

Strong industry involvement in core technology development.

-

Expected Outcomes

-

Acceleration of large-scale coal gasification projects.

-

Development of indigenous technology ecosystems.

-

Contribution to energy security, reduced import dependence, cleaner coal utilization.

-

Roadmap for commercial adoption with policy & financial support.

Chemicals from Coal Gasification

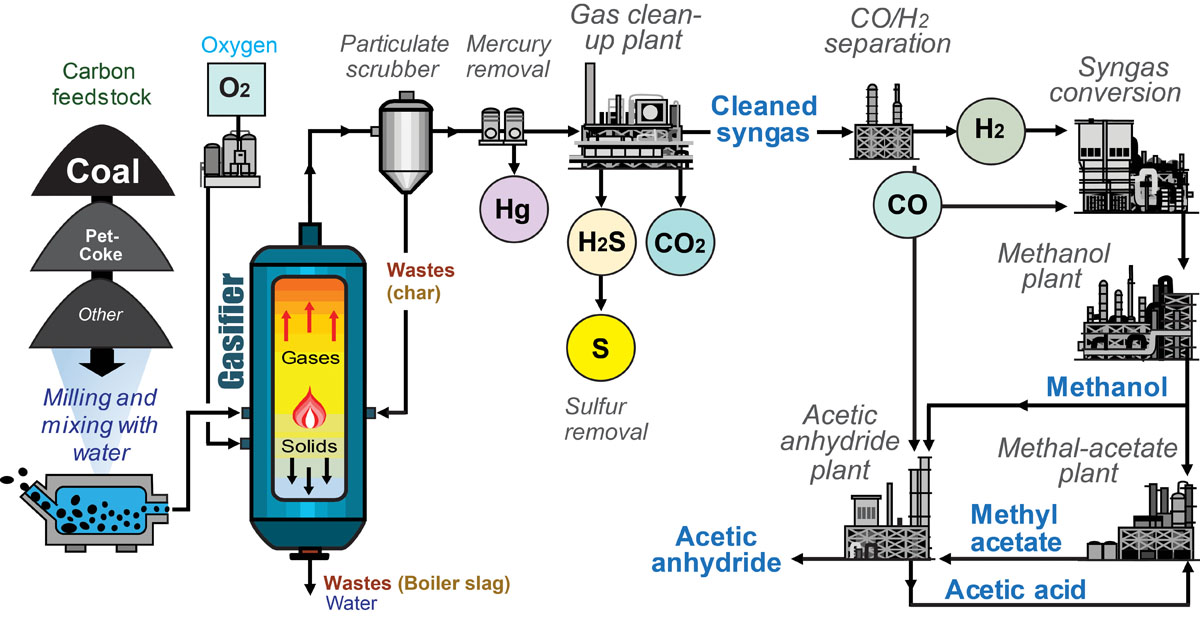

Process

-

Gasification vs Combustion:

-

Combustion → burns coal directly for heat & power.

-

Gasification → coal + water (slurry) + oxygen → thermal-chemical breakdown → produces syngas.

-

-

Syngas Composition:

-

Mainly Carbon Monoxide (CO), Hydrogen (H₂), Water Vapor (H₂O) + minor gases.

-

Acts as a building block for fuels, electricity, and chemical products.

-

Industrial Example

-

Feedstock: Coal or coal + pet-coke mix.

-

Steps:

-

Particulates removed.

-

Purification: Removal of Hg, H₂S, CO₂.

-

Sulfur recovered as elemental sulfur (S).

-

-

Syngas separation → CO + H₂ (feedstocks).

-

Conversion to Methanol (CH₃OH).

-

Derivatives:

-

Methyl acetate → Acetic acid & Acetic anhydride.

-

Acetic anhydride: Used in photographic film, textiles, plastics, pharmaceuticals.

-

-

Key Products from Coal Gasification

-

Methanol – precursor for formaldehyde, olefins, fuels.

-

Ammonia (NH₃) – fertilizers, explosives.

-

Urea – nitrogen fertilizers.

-

Hydrogen (H₂) – refining, steel, green fuel.

-

Carbon Monoxide (CO) – acetic acid, plastics, resins.

-

Synthetic Natural Gas (SNG) – substitute for natural gas.

-

Acetic Anhydride – textiles, film, industrial solvents.